REKIS Croatia: High-purity rPET is used to make new bottles

Reliable and precise sorting with multisensor sorting systems from Sesotec

Schönberg, November 2023. Croatia‘s accession to the European Union has also given a significant boost to the topic of recycling, among other things. Since then, the aim has been to implement the EU‘s waste directives and current targets and, above all, to drive forward the circular economy to a national level. The EU target of recycling more than 65 percent of the municipal waste generated by 2035 has paved the way for a sustainable circular economy.

Plastic packaging manufacturers in the circular economy

An example from the field of plastic packaging shows that especially the distributors and manufacturers of such packaging who see it as their duty to make their contribution to the circular economy and thus to environmental protection and resource conservation. The aim is to use recycled PET material in the production of PET beverage packaging and to continuously increase its share. When using recycled PET, purity is the decisive factor. Only pure and highquality recyclate can be used for a wide range of new products and especially for beverage packaging.

rPET pellets for use in the food sector

Austrian beverage producer Steinrieser and the newly founded Austrian-Croatian trading company for beverage production KIS pica d.o.o. have joined forces to set up a PET recycling plant in the Donja Dubrava region of Croatia to reprocess disposed plastic bottles.

The PET recycling plant REKIS d.o.o. produces up to 18,000 metric tons of high-quality rPET pellets annually, which is then reused for the production of beverage bottles. In Croatia, plastic bottles are collected via the existing deposit system, but also via municipal collection points. In addition, REKIS sources collected plastic bottles from Austria, Slovenia, Slovakia and the Czech Republic.

Multi-stage sorting process

The material is delivered pressed into bales, separated and forwarded via an eddy current separator for separation from aluminum cans. In order to obtain pure PET material for use in the food sector from the plastic bottles processed in this way, a multi-stage sorting process follows.

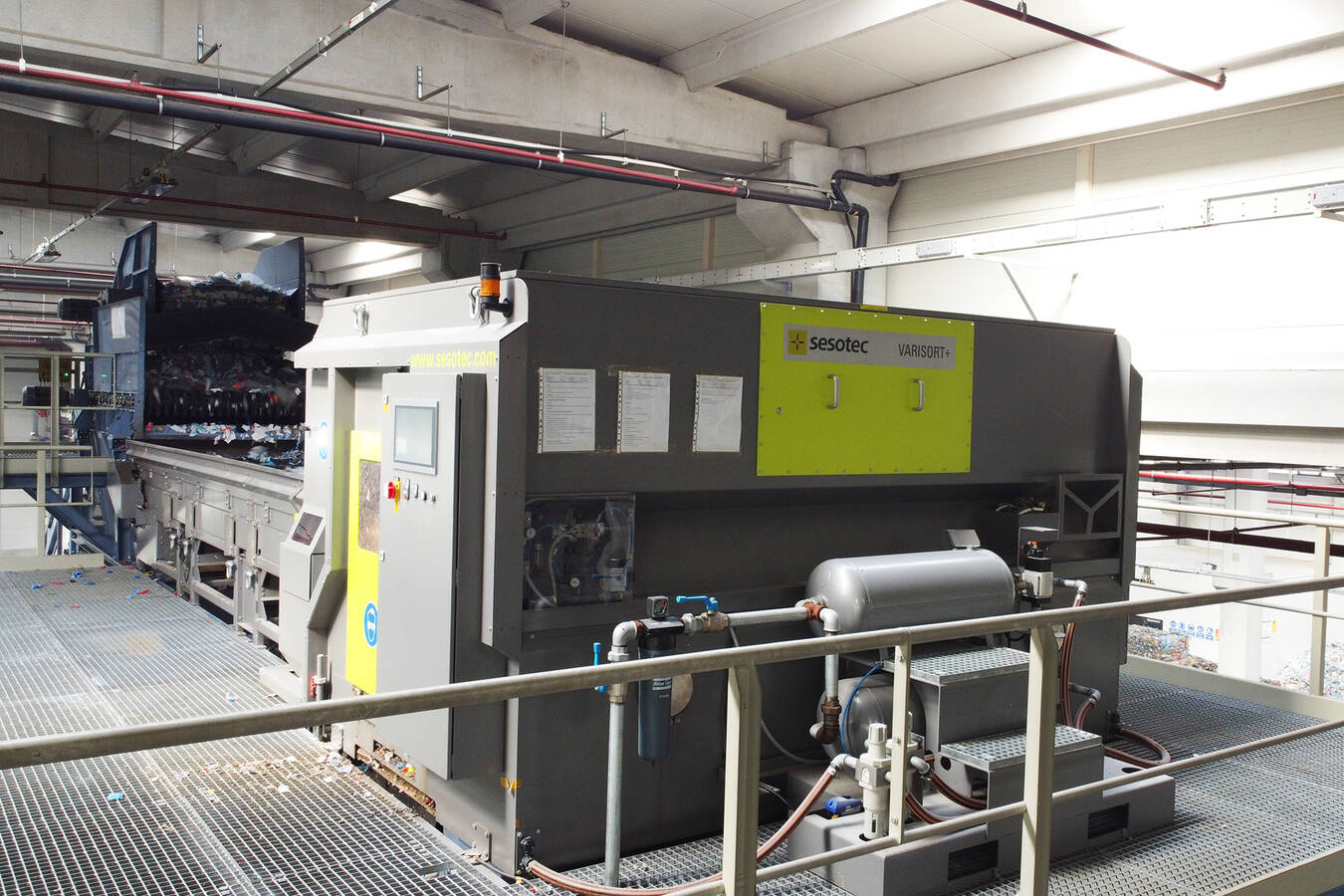

At REKIS, multisensor sorting systems from Sesotec are used to reliably separate plastic bottles and, in a further step, plastic flakes by type. This is the prerequisite for obtaining high-quality rPET pellets.

PRESORTING with VARISORT+ multisensor sorting systems

In the first step, the bottles pass through the VARISORT+ multisensor sorting system. Positive sorting of clear PET bottles takes place: PET plastic bottles and clear bottles are removed and sent to the next sorting stage. Unwanted plastic bottles are actively suppressed and were then sent to the return sorting stage with all other materials.

The advantage of this sorting process is that the target fraction is positively identified and collected. All other materials, such as stones, etc., are removed and no longer interfere with further processing.

QUALITY SORTING of the positively sorted bottles

In quality sorting, the material is examined for foreign materials in order to remove these from the material stream and to ensure the required grade purity. Undesirable polymers (e.g. PVC, PE/PP) as well as colored PET, bottles with labels or even metals are reliably detected and rejected. The VARISORT sorting systems are equipped with Sesotec FLASH technology. This allows especially bottles with special colors (silver, opaque, TiO2 colored) as well as bottles with a very low color saturation, to be detected. This leads to a significant improvement in the quantity of good material and to an increase in safety.

VARISORT+ CMN multisensor sorting system

The remaining, non homogenous material from the two sorting systems is fed to another VARISORT+ CMN multisensor sorting system, where it is again positively sorted for clear PET. What remains is a mixture of colored PET bottles and other waste. Finally, a manual quality control is carried out as well as the use of a metal detection device, which identifies metals before the material enters the granulator.

FLAKE PURIFIER+ CMN multisensor

In the next step, the sorted material is shredded to flakes. This is followed by washing and cleaning processes. Fine sorting of the PET flakes produced by the shredding process is carried out by the FLAKE PURIFIER+ CMN multisensor sorting system. Metals, off-colors and undesirable polymer types are reliably detected and rejected. In order to reduce the loss of good material to a minimum, the material rejected in the first pass is sorted via a resort lane.

High-quality, color and grade-pure rPET

REKIS plant manager Filip Hozjan: “The Sesotec multisensor sorting systems are the heart of our plant. Only reliable and, above all, precise sorting enables us to obtain high-quality, color and grade-pure rPET that can be further processed into food-grade rPET pellets. These high-purity flakes are used by beverage producers as starting material for the production of new bottles. The cycle is closed.“