FreDrive - a distinctly avant -garde, modular concept

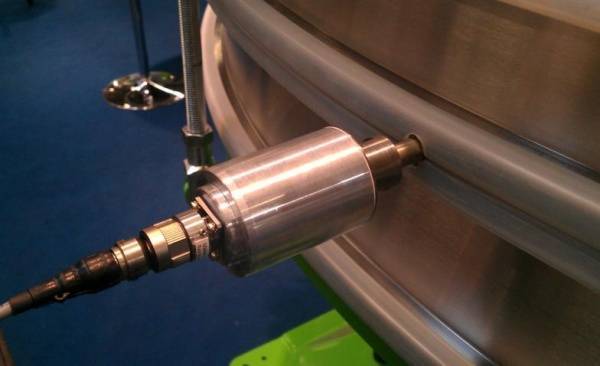

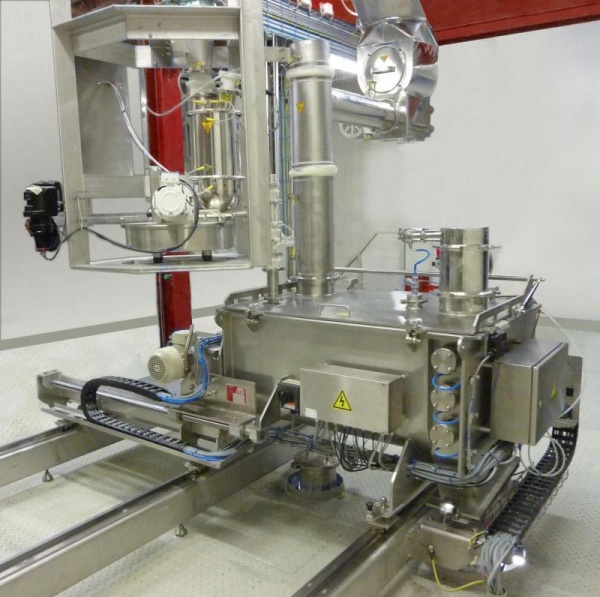

One Platform - 5 milling heads FREWITT, world leader in powder size reduction technologies, presents FreDrive, an innovative technology

combining multiple, milling processes in a single, milling platform dedicated to the pharmaceutical, chemical

and food products industries.

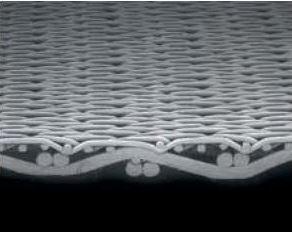

MODULARITY – A distinctly avant-garde, modular concept: FreDrive allows you to alternate, depending on your production requirements, between 5 milling heads for size-specific

crushing, fine grinding, de-agglomeration, or controlled sifting.

FLEXIBILITY – Incomparable versatility: FreDrive allows you to adapt your milling platform easily and quickly, to suit your current or future production requirements, regardless of your

manufacturing environment or production site.

PERFORMANCE – Enhanced by a factor of 5: FreDrive proves its capabilities with the same degree of flexibility across the entire range of your processing needs, from small batch to

large-scale production.

SAVINGS – Enhanced return on investment