Schönberg, September 2022

Sesotec GmbH from Schönberg, a leading metal detection, sorting and analysis system manufacturer, will present its exhibit at the K trade fair in Düsseldorf from October 19 to 26 under the motto ”Economy meets Ecology.” The company thus positions itself as a provider of answers to salient global issues surrounding the circular economy, sustainability, and resource conservation. Sesotec will be exhibiting at booth A40, Hall 10, and at the VDMA Circular Economy Forum ”The Machine.”

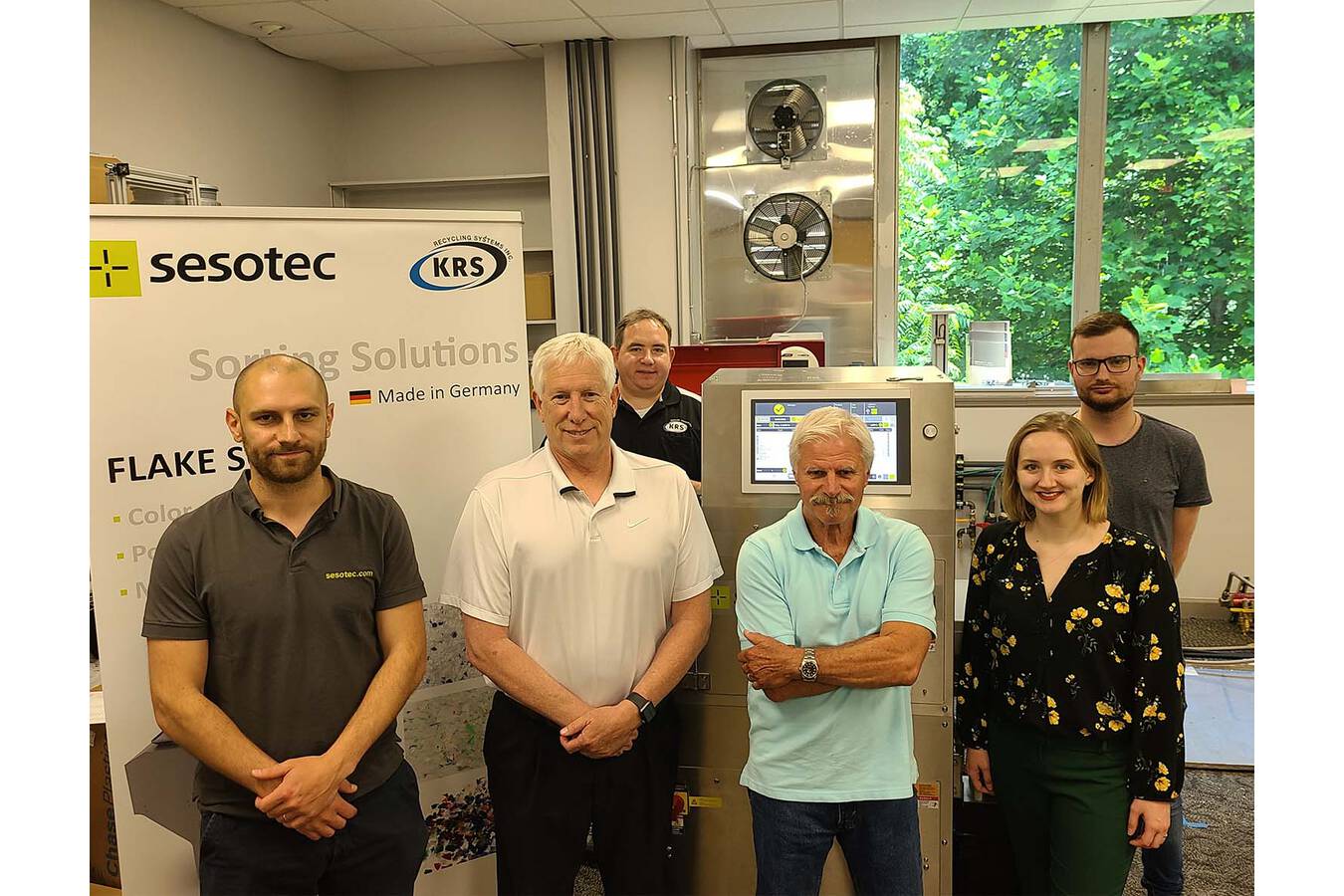

As climate change, the draining of finite resources and the vast amounts of plastic waste in the world’s oceans become key areas of concern in politics, business and society as a whole, the plastics industry is coming under growing pressure. The circular economy poses a variety of challenges for manufacturers, processors and recyclers of plastics – but also offers numerous opportunities. ”We are highlighting important global issues surrounding sustainability, the circular economy and CO2 reduction, and showing the contribution our foreign object detectors, material analysis and sorting systems and services can make to solving these challenges,” says Dietmar Dieing, Sesotec Vice President of Sales for Plastics. ”Whether it’s manufacturing, processing or recycling, we are looking at the entire plastics value chain, and charting a course to help our customers use as few resources as possible while increasing production efficiency and profitability.”

The importance of these topics for Sesotec is also reflected in the physical extension of its booth area to 120 square meters (or 1,292 square feet). Crucial points in the plastics cycle such as tailor-made inspection, analysis, and sorting solutions for all production process stages will be on display in Sesotec’s exhibit.

Artificial intelligence (AI) changes to service and maintenance

Sesotec has expanded its core competence in the field of AI to meet plastic industry customer requirements for greater plant availability, transparency, automation, and profitability. The company will be demonstrating these new features at its K trade fair booth.

In the service area, a range of services have emerged to help customers take the efficiency, productivity, and connectivity of plastics plants – whether in production, processing, or recycling – to a new level. Says Michael Perl, Group Director of Sales Division Sorting Recycling, ”We are looking forward to the K show as a unique opportunity to present Sesotec’s holistic approach: ’Economy meets Ecology.’ That approach is the key to providing answers to the pressing questions of circular economy, efficiency increase, profitability, and sustainability.”

Sesotec equipment highlights at K 2022

- Sorting system FLAKE PURIFIER+

- Material analysis system FLAKE SCAN

- Metal detector GF for pneumatic conveying lines

- Metal separator RE-SORT

- Metal separator PROTECTOR for extruders, injection molding, and blow molding machines

- Metal separator RAPID VARIO with rotating separation unit