Concetti at Powtech 2017

Improving productivity by smart bagging equipment From September 26th to 28th, the latest Concetti equipment and innovations in packaging and filling will be presented at Powtech 2017, the leading trade fair for processing, analysis, and handling of powder and bulk solids, taking place in Nuremberg, Germany.

During Powtech 2017, Concetti, a manufacturer of high quality packaging machinery and a leading supplier of turn key solutions, will showcase the most innovative bagging solutions for the chemical, pharmaceutical, plastic, food-feed and building industries, designed for tomorrow’s smart factory.

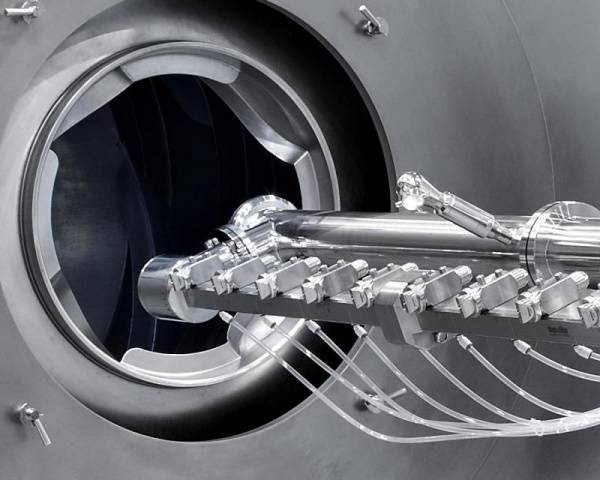

Particular attention will be given to the tubular Form, Fill & Seal “Continua”, for handling extra-fine powders. This range of fully automatic equipment for hermetic and recyclable polyethylene sacks, from 10 to 50 kg, with speeds up to 800 bags/hour and the versatility to provide fast changeover between many different packaging formats. The waterproof, clean and squared bags can be palletised easily reducing