amixon® mixers for instant soups and sauces

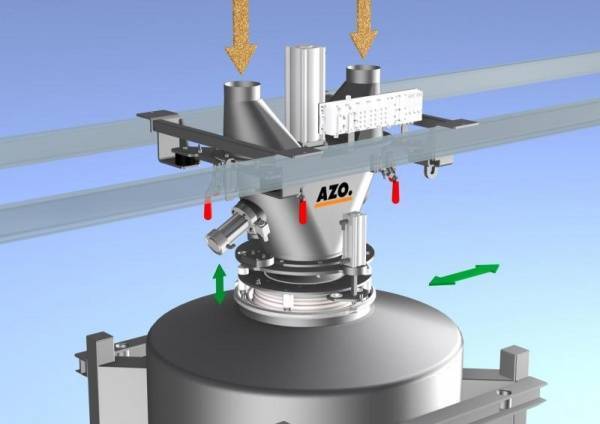

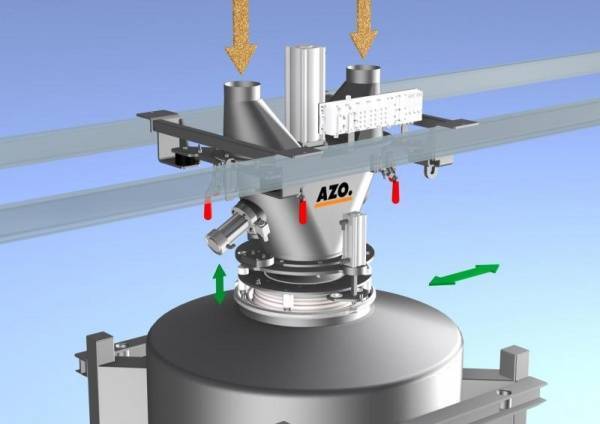

Visit amixon at the Powtech 2017 The recipe of the mixture in this mixing task is very complex. The components consist of large, small, round, square, and rectangular particles, such as: dried vegetables, ground spices, natural aromas, liquid extracts, stabilizers, enzymes and many others.

The mixing process in the amixon® mixer takes place in two steps. In the first step, the powdery components are intensively moistened with liquid additives such as oil, fat, spice extract, oleoresin, and lecithin. In the same mixer step 2 follows: The fragile components are added (dill tips, onion rings, mushrooms, etc.) and are gently folded in. The end product flows easily and is free from dust. The coarse particles do not break.

The ”multi-step” process takes place with minimal energy input and without a measurable increase in tempera-ture. The same mixer performs both mixing processes: intensive deagglomeration with very high energy input and gentle homogenizing with low energy input.

amixon® apparatuses